QueenTech-Food Processing Technology

Affordable Design and Entrepreneurship Capstone Project at Olin College

Debbie Testing Grater

Abstract

Over 10 months, I collaborated as a part of a team of students with a Ghanaian nonprofit to design safer, more efficient cassava grating machines that support women-run garri production microbusinesses.

Through in-country fabrication, user interviews, and iterative prototyping, our team created tools that reduce physical strain and promote economic independence.

This project deepened my commitment to socially responsive design grounded in real-world context.

Under Supervision of Dr Ben Linder at Olin College

Role: Product Design & Field Testing

Team Size: 6

Duration: 10 months

Partner: QueenTech Initiative (Ghana-based nonprofit)

Location: Olin College & Kumasi, Ghana

Team Size: 6

Duration: 10 months

Partner: QueenTech Initiative (Ghana-based nonprofit)

Location: Olin College & Kumasi, Ghana

As part of my senior capstone at Olin College, I joined a long-running social impact project in collaboration with QueenTech, a women-run Ghanaian nonprofit. QueenTech designs, builds, and sells affordable cassava graters and presses to women in rural Ghana who produce and sell garri, a staple West African food made from cassava.

Traditionally, garri production involves labor-intensive, time-consuming hand grating, work that is physically taxing and inefficient. The machines we helped develop were designed to reduce this burden, improve safety, and support women’s microenterprises across rural Ghana.

In this project, I contributed to product iteration, on-the-ground fabrication, field testing, and user-centered design. I led the design of two mechanical components, conducted interface and usability assessments, and analyzed material loss during manufacturing. Over two trips to Ghana, I worked closely with users to understand how our technology fit into their lives and contributed to their independence and income generation.

This experience fundamentally shaped how I think about engineering for social value and long-term impact.

Overview

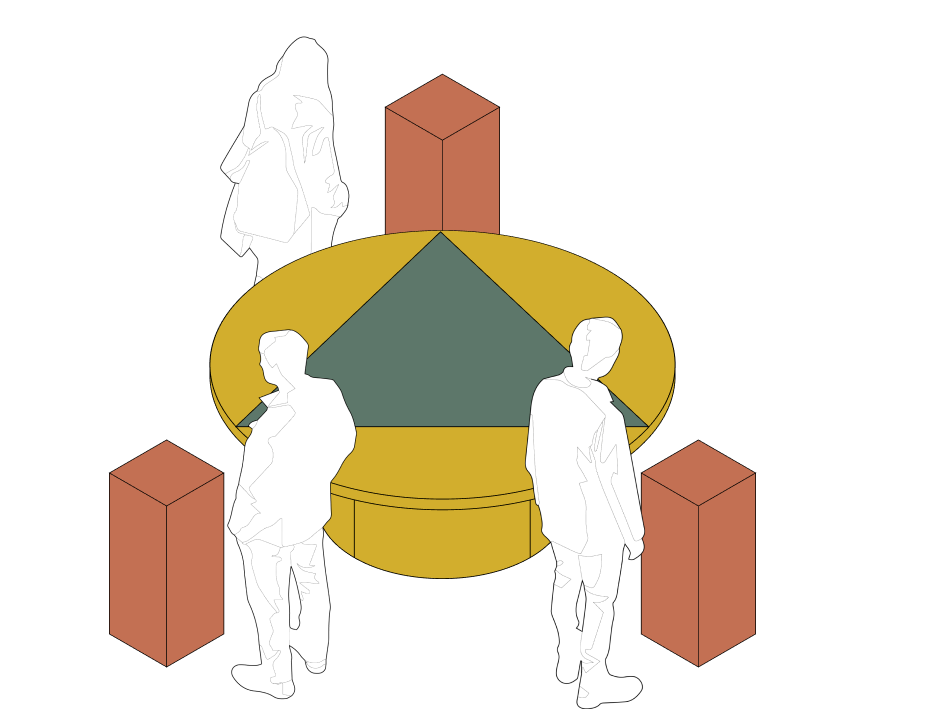

Exploded View of G17 Grater

How can we design agricultural tools that support traditional practices while reducing harm and increasing agency for users?

Our team inherited the 16th iteration of a cassava grater developed over seven years of partnership between Olin College and QueenTech. The challenge was to evolve this system into something safer, easier to use, and more reliable for the women running home-based garri businesses. Each design decision needed to reflect not just performance metrics, but also the lived realities of our users: how they clean the machine, store it, and share it.

The Challenge

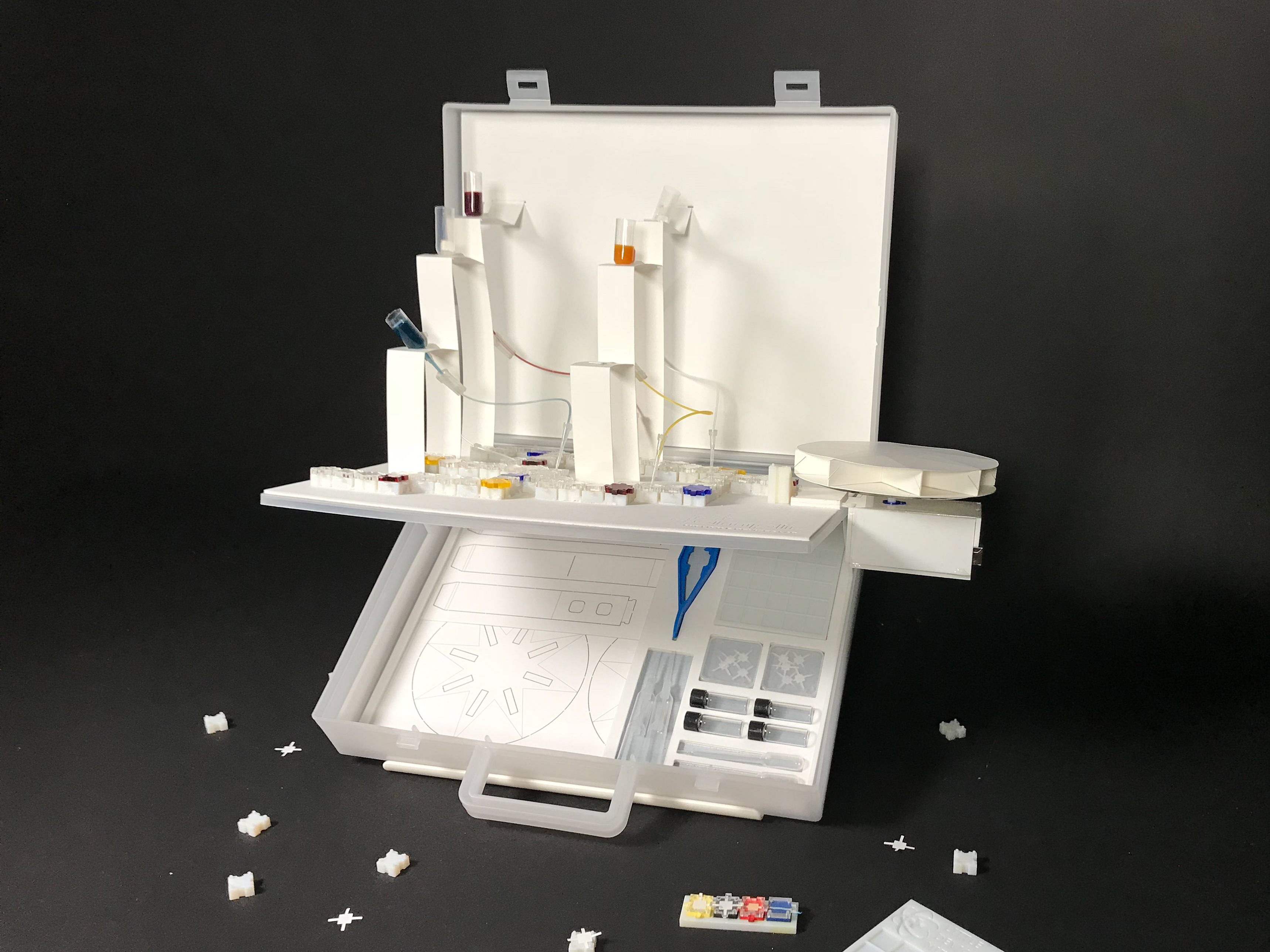

We traveled to Ghana twice, once in August 2019 and again in January 2020, to fabricate, test, and refine new iterations of the grater. Working from a university machine shop at KNUST (Kwame Nkrumah University of Science and Technology), we built two improved versions of the machine with updated architecture and materials.

We conducted in-home user interviews, learned about garri production, observed how the graters were being used and cleaned, and performed repairs on older units. We left a prototype with one of our long-term testers, Hawwa, and collected feedback over several months.

From this feedback, I was tasked with solving a key safety issue: the rotating grater head could shift during operation, posing risks to users and damaging the machine. I prototyped and implemented a successful head retention mechanism, which we tested in the field and integrated into future designs. Our team also fabricated five additional 17th-generation graters in January for wider testing and distribution.

Our Approach

G17 Grater

• Led the design and field testing of two mechanical components, including a successful redesign of the grater head retention system.

• Conducted in-home user interviews and usability testing, including ergonomic and cleaning assessments.

• Fabricated and assembled sheet metal components in the field.

• Analyzed and documented material loss patterns during manufacturing to reduce waste and cost.

• Worked closely with end users, listening to feedback and iterating on solutions in real-time.

My Contribution

This project showed me how engineering can empower. Working alongside local partners and women business owners, I saw the impact that thoughtful design can have on autonomy, dignity, and income.

I learned how to listen deeply, not just to feedback, but to context. Technical performance matters, but so does social and cultural fit. I gained experience in low-resource fabrication, rapid iteration under time pressure, and cross-cultural collaboration.

Most importantly, I learned that designing for social value means practicing humility, building trust, and being open to change.

What I Learned

Machine Tester Abigail

Machine Tester Hawwa

This project was not just about building better machines—it was about supporting the independence of women building businesses in rural Ghana.

The ability to work from home meant women could earn income while caring for their families, avoid long commutes, and process more cassava than by hand.

By building with, not just for, our users, we created tools that served real needs and fit real lives.

This experience continues to shape how I think about equity, sustainability, and long-term impact in design work.

Reflections

Olin, KNUST, and QueenTech Team