Ampli Blocks

Modular Medical Diagnostics and Drug Production Kit for Low-Resource Settings

Abstract

Ampli Blocks is a modular, paper-based medical kit developed at MIT’s Little Devices Lab, designed to make medical diagnostics and drug production accessible in low-resource communities. Originally focused on diagnostics, the system uses modular "blocks" pre-loaded with reagents, assembled in different configurations for customized medical tests. I joined the project to design and prototype a new drug production system element. This portable, foldable assembly enables on-site medication production using chromatography paper and minimal tools.

Role: Product Designer (Prototyping and Systems Design), Fabricator

Tools: Laser Cutter, Adobe Illustrator, Origami Folding Techniques, Cardstock Prototyping

Timeline: June – September 2018

Tools: Laser Cutter, Adobe Illustrator, Origami Folding Techniques, Cardstock Prototyping

Timeline: June – September 2018

Access to essential diagnostics and medications is often limited in resource-constrained environments. While the Ampli Blocks kit provided customizable diagnostics, it lacked a system for producing medications on-site. The challenge was to design a drug production mechanism that:

• Could be assembled by non-engineers in the field

• Shipped flat, was inexpensive, lightweight, and easily replaceable

• Maintained a clean, clear visual design for public exhibition

We Asked

How might we design a modular drug production system compatible with Ampli Blocks that is affordable, field-ready, and visually demonstrative of the project’s mission?

The Problem

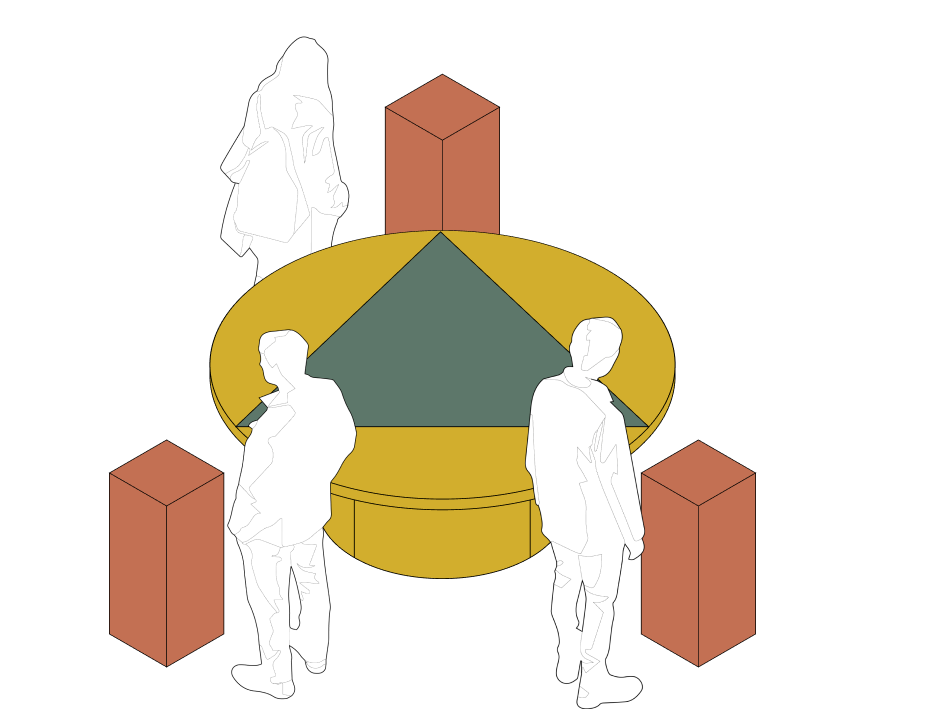

We proposed a foldable, cardstock-based drug production assembly composed of collapsible chemical drip stands and a chromatography paper collection wheel. The system would ship flat for portability and pop up during use, following origami-inspired principles.

System Proposal: Production Setup

1. Drip Stands: Lightweight, foldable stands for holding chemical solutions

2. Collection Wheel: A rotating wheel to collect the produced medication onto chromatography paper

The Proposal

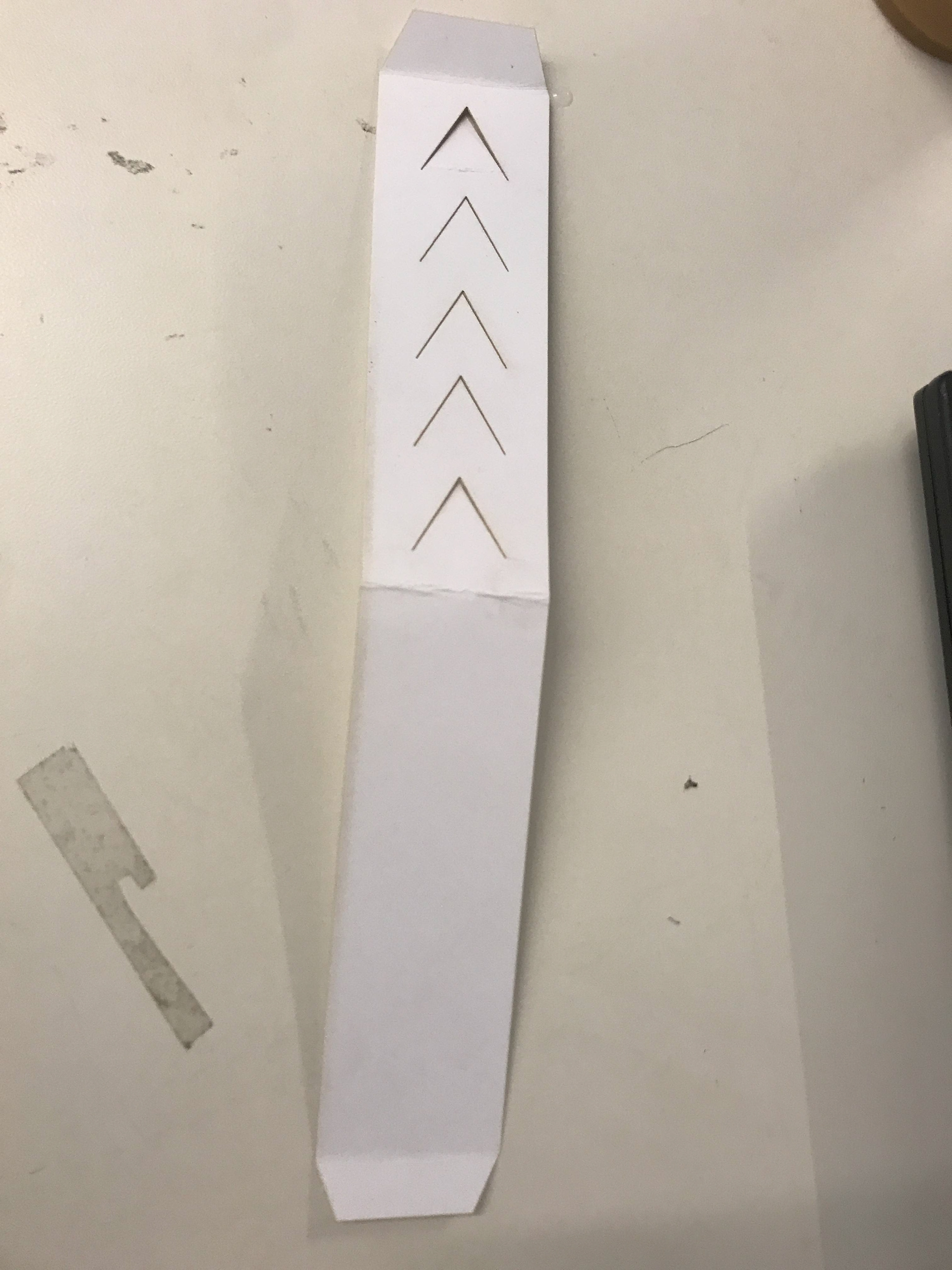

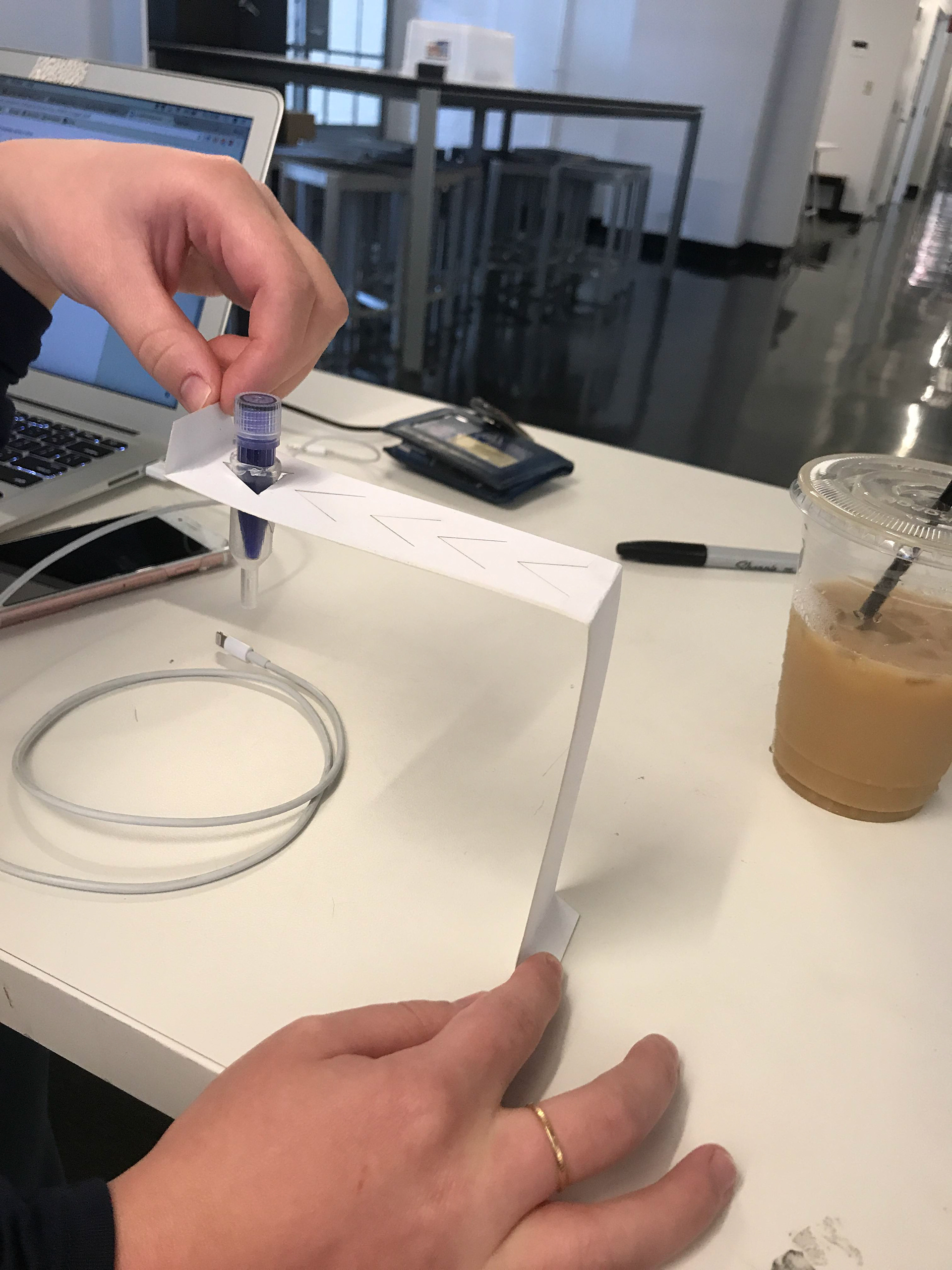

Chemical Drip Stands:

I designed a semi-permanent stand system using laser-cut cardstock etched with fold guides, inspired by origami structures from Folding Techniques for Designers by Paul Jackson. The stands folded flat within the kit and could be quickly assembled on-site.

I designed a semi-permanent stand system using laser-cut cardstock etched with fold guides, inspired by origami structures from Folding Techniques for Designers by Paul Jackson. The stands folded flat within the kit and could be quickly assembled on-site.

Medication Collection Wheel:

I created a rotating wheel prototype to collect medication on chromatography paper. The wheel was designed for structural stability while remaining lightweight and easy to assemble with minimal components.

I created a rotating wheel prototype to collect medication on chromatography paper. The wheel was designed for structural stability while remaining lightweight and easy to assemble with minimal components.

Fabrication Process:

Through multiple rounds of laser cutting tests and material trials, I optimized etching and cut settings to prevent scorching while ensuring clean fold lines. Iterative prototyping ensured both functional reliability and exhibition-quality aesthetics.

Through multiple rounds of laser cutting tests and material trials, I optimized etching and cut settings to prevent scorching while ensuring clean fold lines. Iterative prototyping ensured both functional reliability and exhibition-quality aesthetics.

Prototype Theme: Low-Cost, Field-Deployable Medical Care

The design prioritized low-cost materials, rapid assembly, and minimal training requirements, in keeping with Little Devices Lab’s mission to decentralize medical technology for underserved communities globally.

Product Prototype

System and Product Design

• Contributed to the ideation and prototyping of the drug production system elements

• Applied origami engineering techniques to develop foldable, modular components

• Designed and tested chemical drip stands and medication collection wheel prototypes

• Contributed to the ideation and prototyping of the drug production system elements

• Applied origami engineering techniques to develop foldable, modular components

• Designed and tested chemical drip stands and medication collection wheel prototypes

Fabrication and Testing

• Conducted laser cutter trials to calibrate cut and etch settings for structural reliability

• Produced final exhibition-ready prototypes for a public museum display

• Conducted laser cutter trials to calibrate cut and etch settings for structural reliability

• Produced final exhibition-ready prototypes for a public museum display

User Experience Design

• Participated in usability testing of prototype assembly and function for non-engineer users

• Ensured flat-pack shipping and easy replaceability of components

• Participated in usability testing of prototype assembly and function for non-engineer users

• Ensured flat-pack shipping and easy replaceability of components

My Contributions

This project expands the capability of Ampli Blocks from diagnostics to on-site treatment, addressing critical gaps in healthcare delivery for low-resource areas. By contributing to accessible, lightweight, and easily assembled medical systems, this work supports global efforts to improve equitable access to essential healthcare tools in the communities that need them most.

Why It Matters